Service Overview

Our services can be requested as a full-package solution, or as individual modules to perfectly fit your specific project needs. You choose what you need, and we deliver.

We offer expert guidance. We optimize your project's architecture, component choices, and development plan.

We handle the full electronic design process. This includes robust circuit engineering, starting from the schematic, up to the final, ready-to-manufacture PCB.

Our team develops custom firmware and software solutions to bring your hardware to life, from embedded systems to cloud applications.

We simplify your supply chain by handling the sourcing of high-quality components and PCBs, ensuring a smooth and efficient production.

We offer rapid and precise prototyping to validate designs and ensure seamless transition to mass production.

Our integrated process ensures cost-effective production for small to mid-volume batches, guaranteeing quality at every step.

We perform rigorous testing to ensure your product meets the highest standards for performance, reliability, and functionality.

Consulting & Project Scoping

Every great product begins with a solid plan. Our consulting services are designed to help you transform your initial idea into a clear and viable project. We work closely with you to define the scope, identify potential challenges, and lay the groundwork for a successful and efficient development process.

We help you with:

Analysis: Assessing the technical and commercial viability of your concept.

Technology Stack Selection: Recommending the optimal hardware and software platforms for your project.

Cost & Timeline Estimation: Providing a detailed roadmap with realistic budget and schedule projections.

Risk Assessment: Identifying and mitigating potential design, manufacturing, and supply chain risks.

Design for Manufacturing (DFM): Ensuring your product is designed for efficient and cost-effective production from day one.

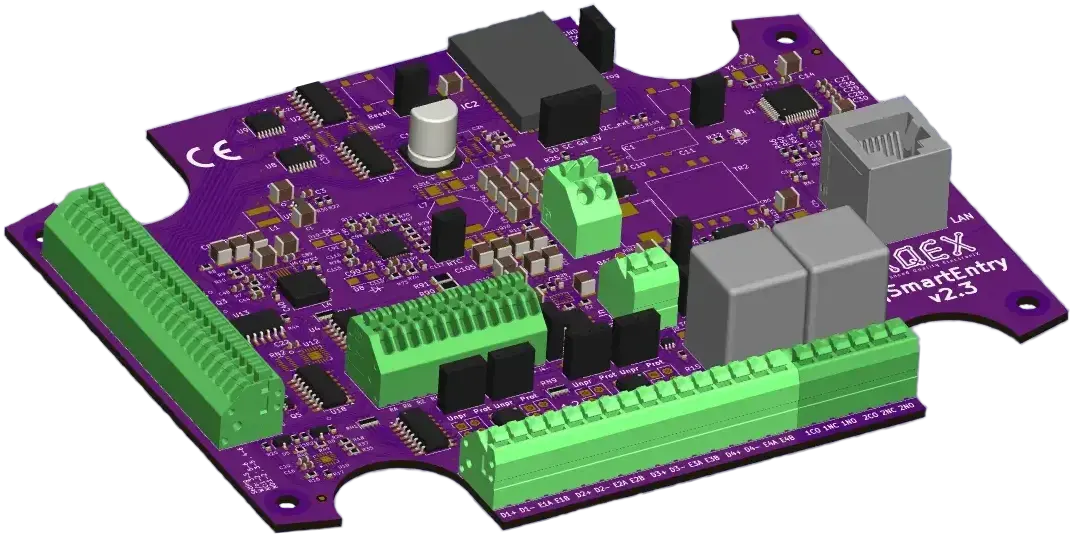

Hardware Design

Our experts specializes in designing robust and reliable hardware solutions from the ground up. We manage every stage of the process, from initial schematic capture to the final PCB layout, ensuring every component is perfectly integrated for optimal performance.

What We Do Best:

PCB Design: Single-layer, multi-layer, and high-density layouts.

Component Selection: Sourcing and management of cost-effective and reliable parts.

Specialized Designs: Analog, digital and mixed-signal circuit design.

Manufacturing Files: We deliver complete Gerber, BOM, and Pick & Place files ready for production.

Software Engineering

We specialize in bringing hardware to life with clean, efficient, and well-documented code. We build custom firmware and applications that ensure your device performs seamlessly and connects reliably. We focus on creating intelligent, responsive systems that deliver the best user experience.

Our Expertise Includes:

Embedded Firmware Development: We build robust and optimized firmware for microcontrollers and embedded systems.

IoT & Connectivity: Our solutions connect your devices to the internet via Wi-Fi, Bluetooth, or other protocols, enabling remote control and data collection.

Custom Device Drivers: We create specialized drivers for sensors, displays, and peripherals, ensuring seamless communication between your hardware components.

Platform Expertise: Our team has extensive experience with platforms like ESP32 and Raspberry Pi, and we are proficient in multiple programming languages to meet your project's needs.

Part & PCB Sourcing

Navigating the complexities of the global supply chain can be a major challenge. We simplify this process by handling the entire procurement of components and PCBs for your project. Our established relationships with trusted suppliers ensure you get high-quality materials at competitive prices, on time.

We Ensure:

Reliable Component Sourcing: Access to a global network of qualified suppliers for all your component needs.

Cost & Lead Time Optimization: We actively work to find the best balance between cost, availability, and delivery time.

Bill of Materials (BOM) Management: Accurate and efficient management of your entire component list to prevent errors during production.

Quality Assurance: We verify that all sourced parts meet the required specifications and quality standards.

Prototype Production

Before committing to large-scale production, prototyping is a critical step. We offer rapid and precise prototype production services to validate your design, identify potential issues early, and ensure a seamless transition to the manufacturing stage. Our process helps you save time and reduce costs in the long run.

Key Benefits:

Fast Turnaround: Quick and efficient prototype manufacturing to accelerate your product development cycle.

Design Validation: We build and test physical prototypes to confirm the functionality and performance of your hardware and software.

Risk Reduction: Early identification and resolution of potential design or manufacturing issues, preventing costly mistakes down the line.

Production-Ready Feedback: We provide detailed feedback to optimize your design for manufacturability and cost-effectiveness.

Mid-scale Manufacturing

After successful prototyping, the next step is bringing your product to market. We specialize in low to mid-volume manufacturing, providing a seamless and cost-effective transition from design to production. Our hands-on approach ensures consistent quality and allows for greater flexibility and control throughout the entire manufacturing process.

Our Manufacturing Services Include:

Production Planning: We manage the entire manufacturing process, including logistics, to ensure timely and efficient assembly.

Quality Control: Each product undergoes rigorous testing and inspection to meet the highest quality and reliability standards.

Supply Chain Management: We ensure a steady and reliable supply of components, mitigating delays and managing inventory.

Final Assembly & Packaging: We can handle the complete assembly, final testing, and packaging of your product, ready for shipment.

Test & Quality Assurance

Quality and reliability are paramount. Our dedicated testing and quality assurance services ensure that every single product meets the highest standards for performance and functionality. By implementing rigorous testing protocols at every stage, we identify and resolve issues early, guaranteeing a flawless end product and preventing costly recalls.

Our Quality Protocols:

Functional & Performance Testing: Comprehensive testing to verify all features and performance metrics of the hardware and software.

Hardware/Software Integration Testing: We test the seamless communication between electronic components and firmware, ensuring the entire system functions as a cohesive unit.

In-Circuit & End-of-Line Testing:: We use automated and manual test equipment to verify PCB functionality and to perform a final inspection of every unit before shipment.

Manufacturing Quality Control: We monitor and control the production process to ensure consistent quality and reliability across all batches.